Activated sludge design values vs reality

Aug 20, 2025

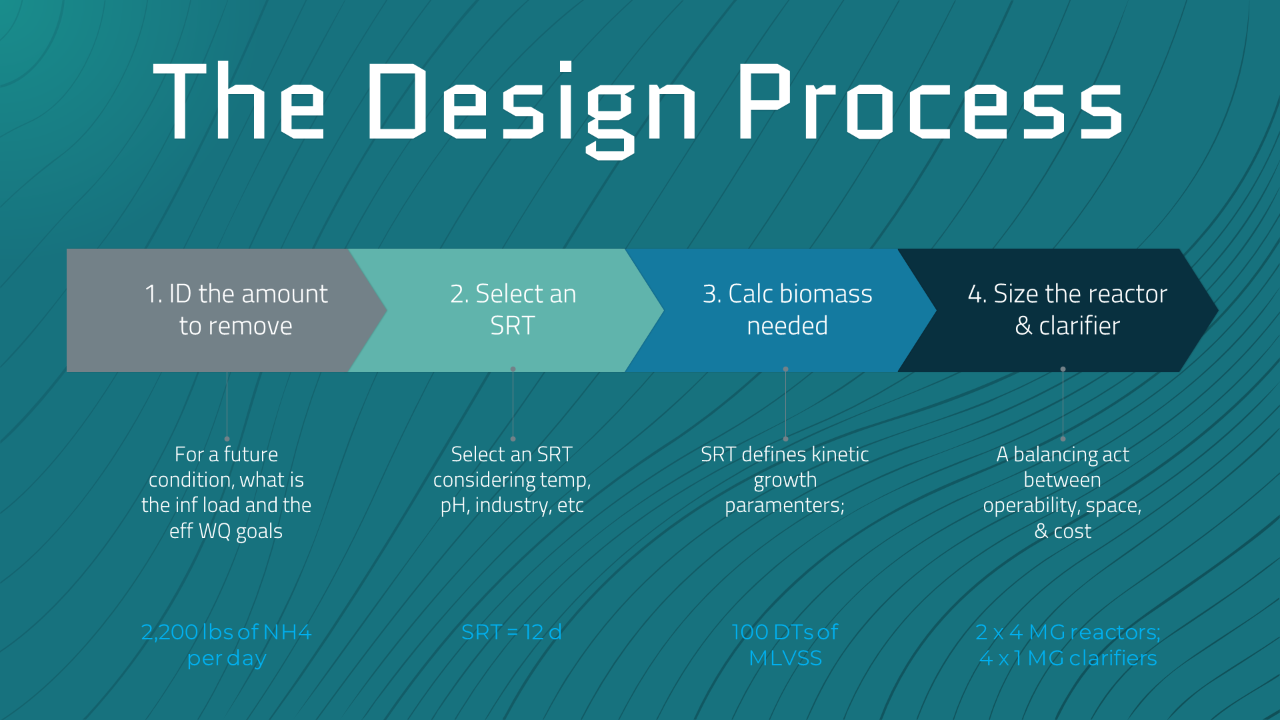

The O&M manual and/or design drawings for a wastewater treatment facility should include a basis of design documenting the design SRT, MLSS concentration, and F:M ratio, along with Raw influent flows and pollutant concentrations. Facilities are designed for a future flow and load, often estimated to occur +20 years in the future. The design MLSS would be the resulting concentration if those flows/loads occurred and the plant was operated at the design SRT. This exact combination of variables can never happen in operation because:

- The actual loads are difficult to predict because flows concentrations vary daily

- WWTPs will never operate at the design condition (which is 100% capacity). It’s illegal. WWTPs will be expanded at 80 or 90% capacity and at that point you’ll get all new design values

If you’re controlling the activated sludge process at the design MLSS concentration, you are holding more biomass in the system than required. And that is likely hurting you here:

- Air demand / Aeration energy – more MLSS requires more air and more $$ to run blowers

- Clarifier capacity. More MLSS increases solids loading to clarifiers and suppresses the clarifier's ability to handle higher flow rates

- Digestion performance (VS destruction). Longer SRTs in the aeration basin will decrease the amount of VSS available for destruction, making it tough to hit a %VS destruction value

If you are experience challenges like this you should consider taking a closer look at your wasting practices. Specifically, how stable your operating SRT is.