The Blog

Understanding the biological players in wastewater treatment is essential for sustainable team/facility management and individual professional growth. Ultimately, for a facility this knowledge transl...

Secondary clarifier capacity changes in step with how well the mixed liquor settles. So, having insight into that settleability helps us understand how much flow the clarifiers can handle before bad ...

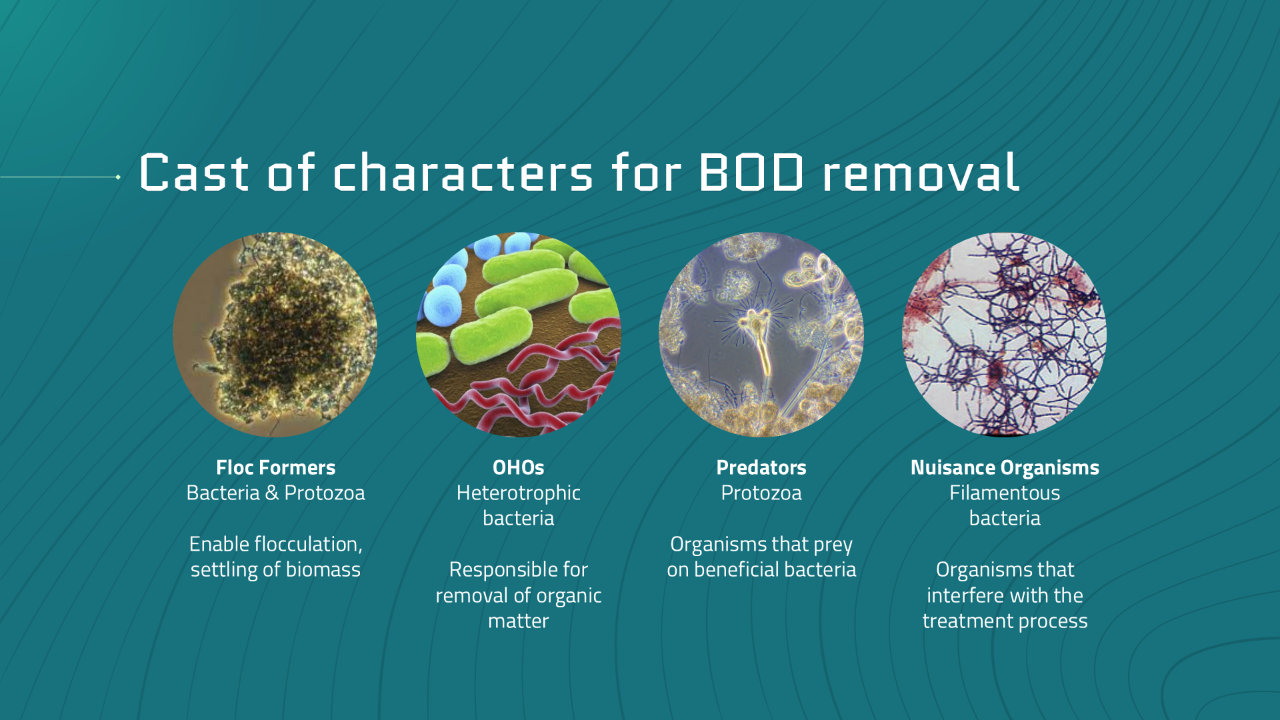

Understanding the factors that affect sludge production fosters a deeper understanding and equips operators to respond proactively to daily system changes which ultimately translates to consistent reg...

Secondary clarification is essential in biological wastewater treatment, especially in suspended growth systems. Its main purpose is to separate the biological floc (biomass) from the treated liquid. ...

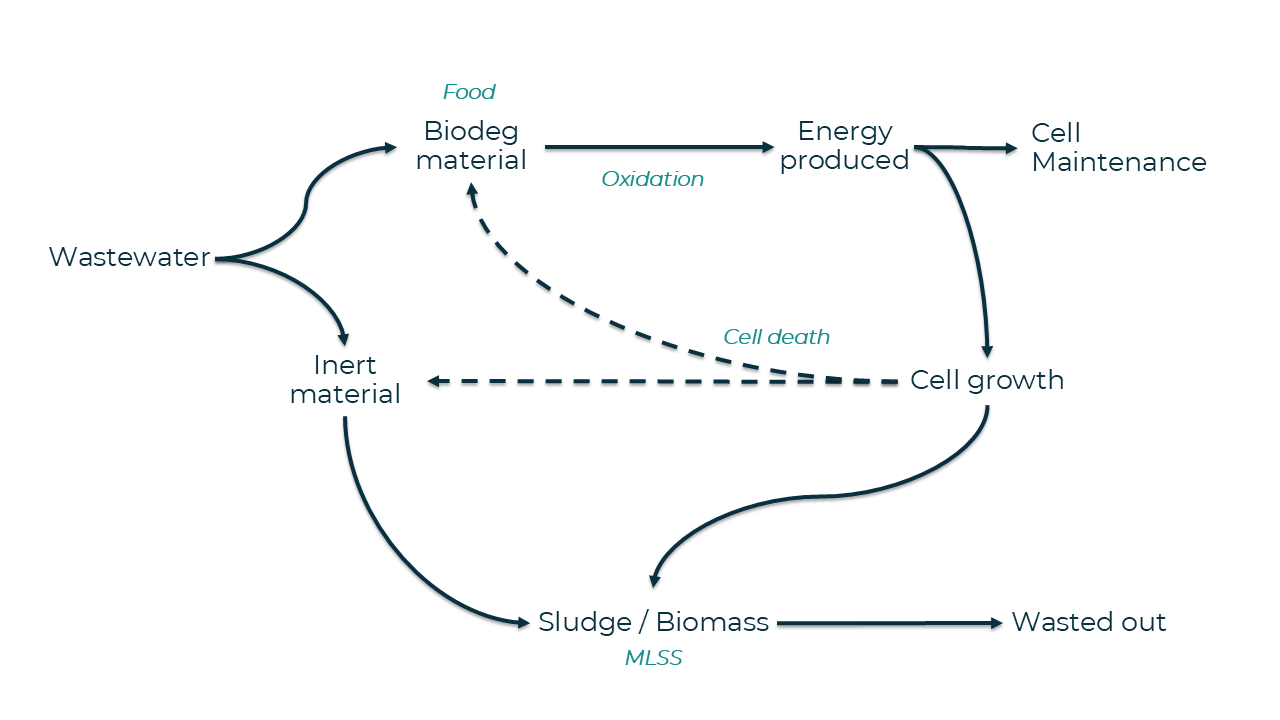

The O&M manual and/or design drawings for a wastewater treatment facility should include a basis of design documenting the design SRT, MLSS concentration, and F:M ratio, along with Raw influent flows ...

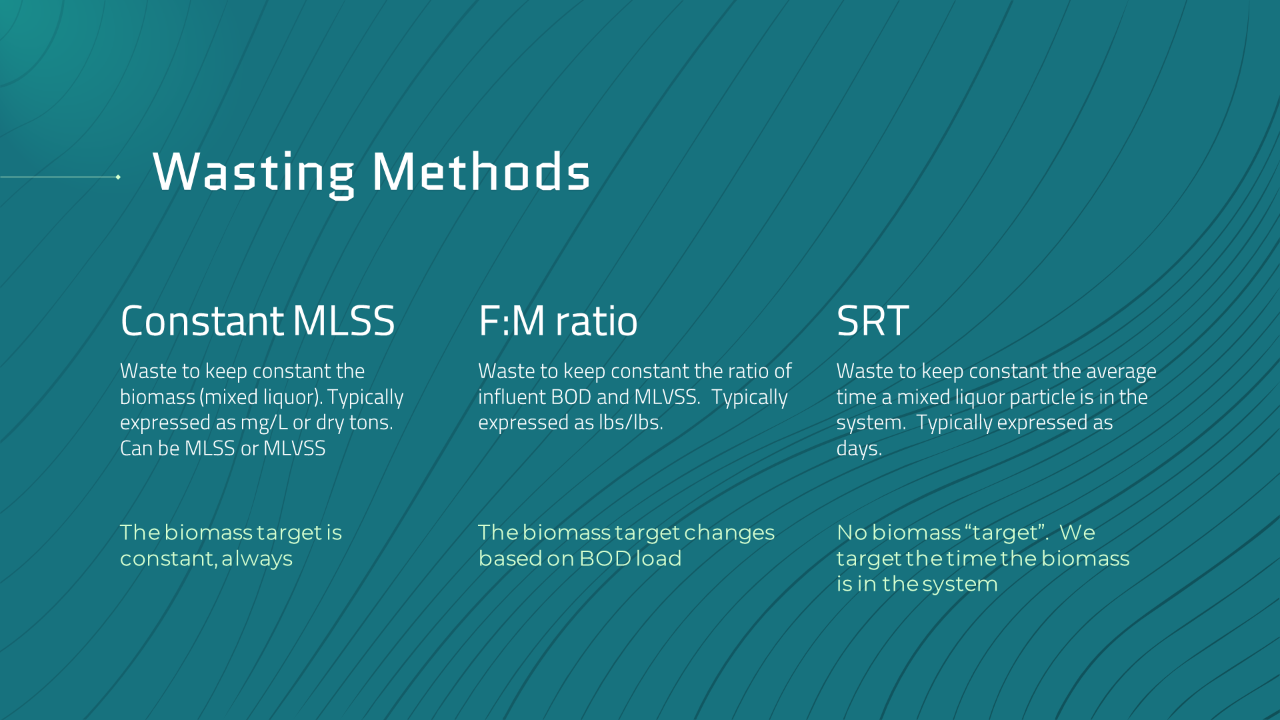

There are three key biological design variables for the activated sludge process: Solids Retention Time (SRT), mixed Liquor Suspended Solids (MLSS) concentration, Food to Mass Ratio (F:M). Either can ...

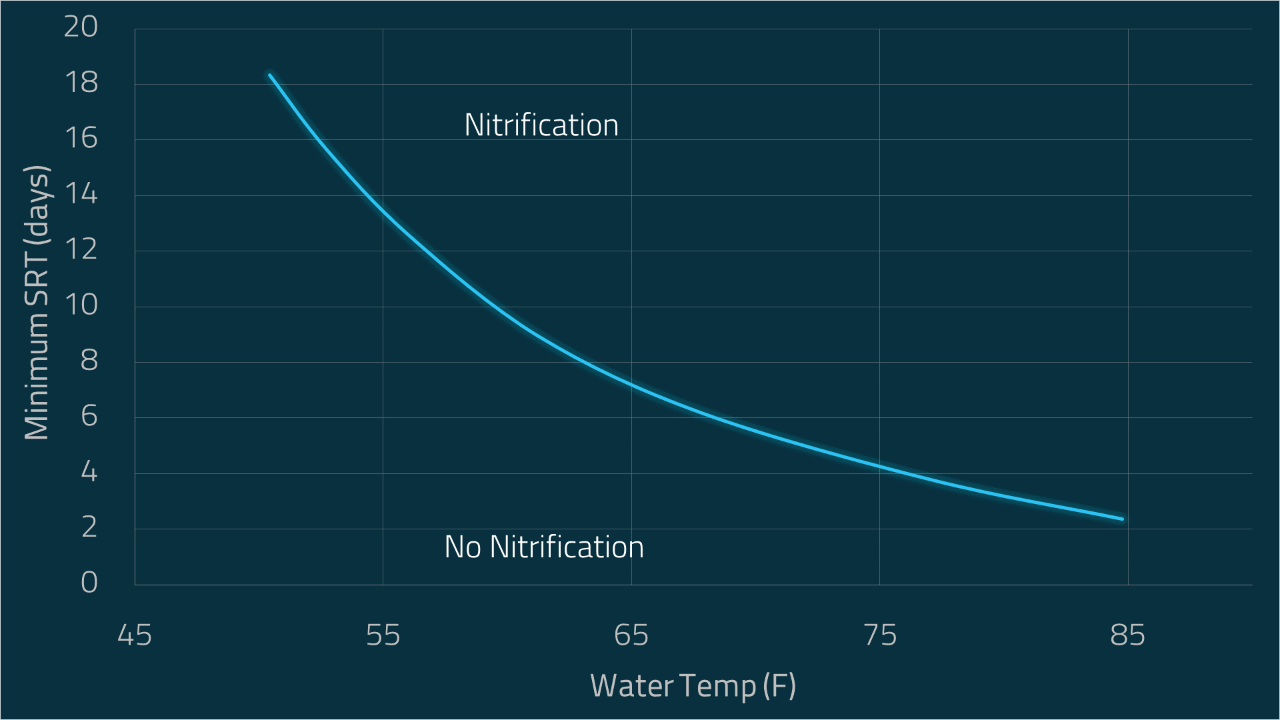

The target or operating solids retention time (SRT) depends on treatment goals and water temperature. Nitrifying bacteria are especially sensitive to water temperatures; growth rates slow as temperat...

Solids Retention Time (SRT) is directly related the growth rate of the biology we are relying on for treatment. Different microorganisms grow at different rates. Nitrifiers in particular are known t...

Solids Retention Time (SRT) is the average time the biomass stays in the activated sludge system…the time in days a particle moves around in the aeration basin and clarifier before being wasted out of...

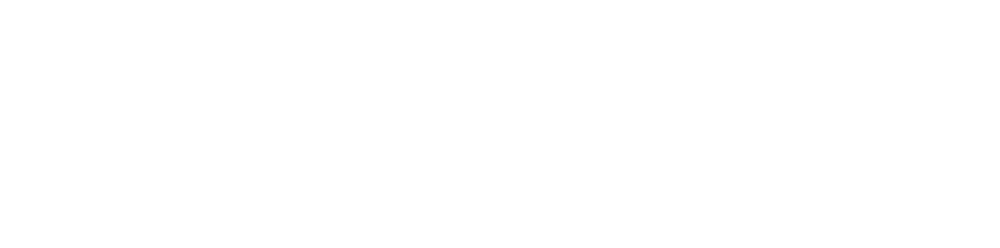

The activated sludge system relies on biology to remove pollutants. Due to biological growth behavior, every pound of pollutant (e.g. BOD or ammonia) we remove will produce a fixed amount of new biom...

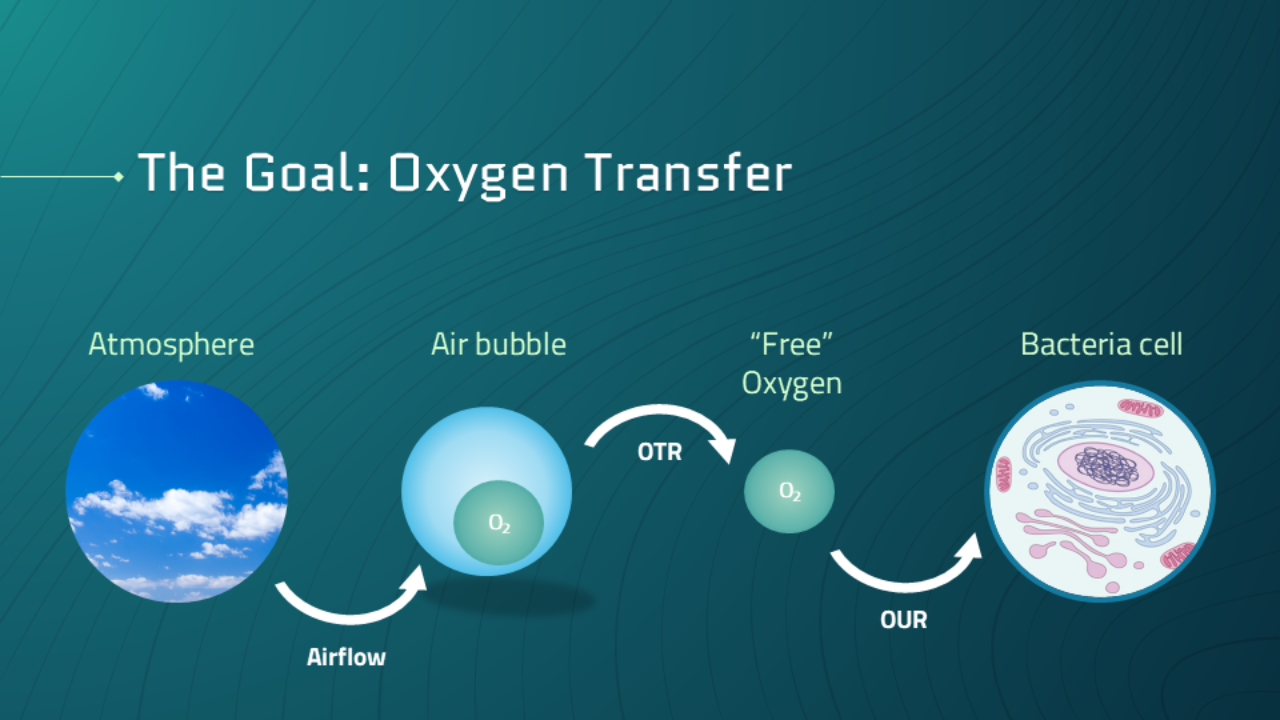

Oxygen uptake rate (OUR) is the rate of oxygen transferred from the bulk liquid to microorganisms; it is sometimes referred to as the breathing or “respiration rate”. This is typically measured as mg...

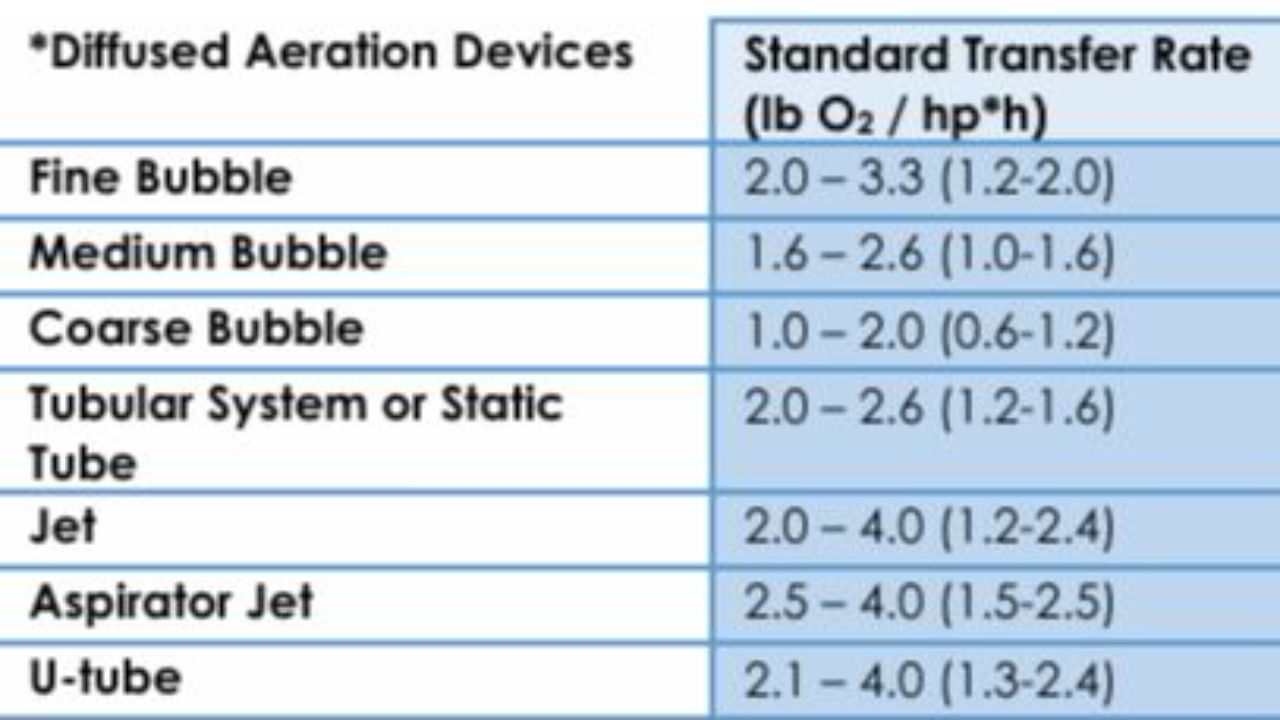

Oxygen transfer rate (OTR) is the rate oxygen is transferred from the air into the bulk liquid of the aeration basin (atmosphere/gas to liquid water). This is typically measured as lbO2/hr. The aerat...