Sticking Together: The Chemistry behind sludge Thickening and Dewatering

Dec 10, 2025

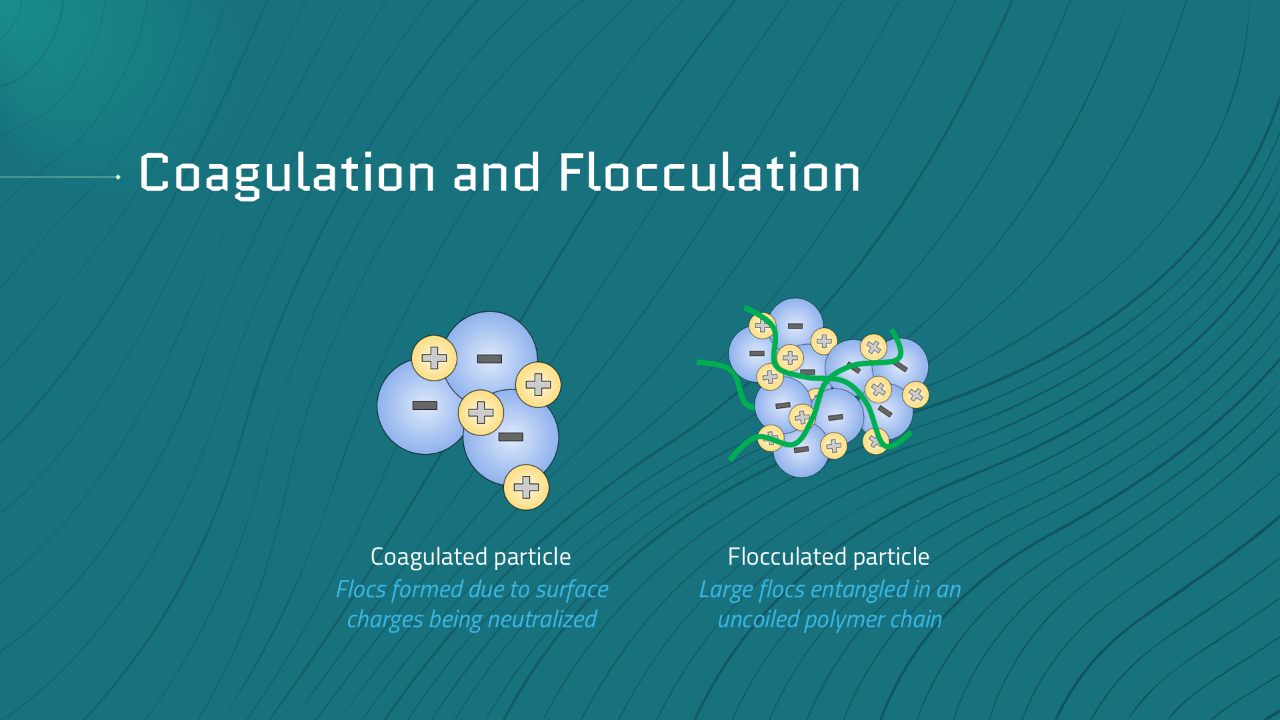

Thickening and dewatering are bookends of your residuals handling process. Your operational knowledge/skill here has direct, whole-plant impacts including treatment performance, permit compliance, and operating costs. In most cases, the sludge we are processing needs to be conditioned prior to thickening/dewatering. Coagulation and/or Flocculation are commonly used to do this. These are two different mechanisms used to turn small particles into big particles:

- Coagulation

- This works by neutralizing charges on the surface of particles.

- Like a magnet, the particles in wastewater often have similar charges and they repel one another. This can prevent smaller particles from becoming larger particles that settle well.

- A coagulant is a chemical added to neutralize the surface charge, and this enables the particles to get closer and form larger particles

- Flocculation

- This works by bridging the space between flocs.

- A chemical is added that acts as a “net” gathering and grouping flocs together to create a larger floc particle that settles rapidly. This is what polymer does in thickening/dewatering.

The chemicals (typically polymer) used in sludge conditioning are essential; we can’t thicken or dewater without them. They are also super expensive and from my experience there’s usually a ton of opportunity to improve practices at WWTPs. While industry knowledge and best practices are well defined this info is often hard for staff to access and apply. That’s why I’ve created a roadmap to help all WWTPs optimize polymer use and reduce the associated operating costs. It gathers all the industry knowledge and presents it in an easy-to-follow format. Download it for free here.