Under pressure: Sludge Dewaterability Explained

Dec 31, 2025

Thickening and dewatering are bookends of your residuals handling process. Your operational knowledge/skill here has direct, whole-plant impacts including treatment performance, permit compliance, and operating costs. Often times, removing water from sludge is less about the technology, and more about the sludge quality. Four primary factors affect how “dewaterable” a sludge is. They are:

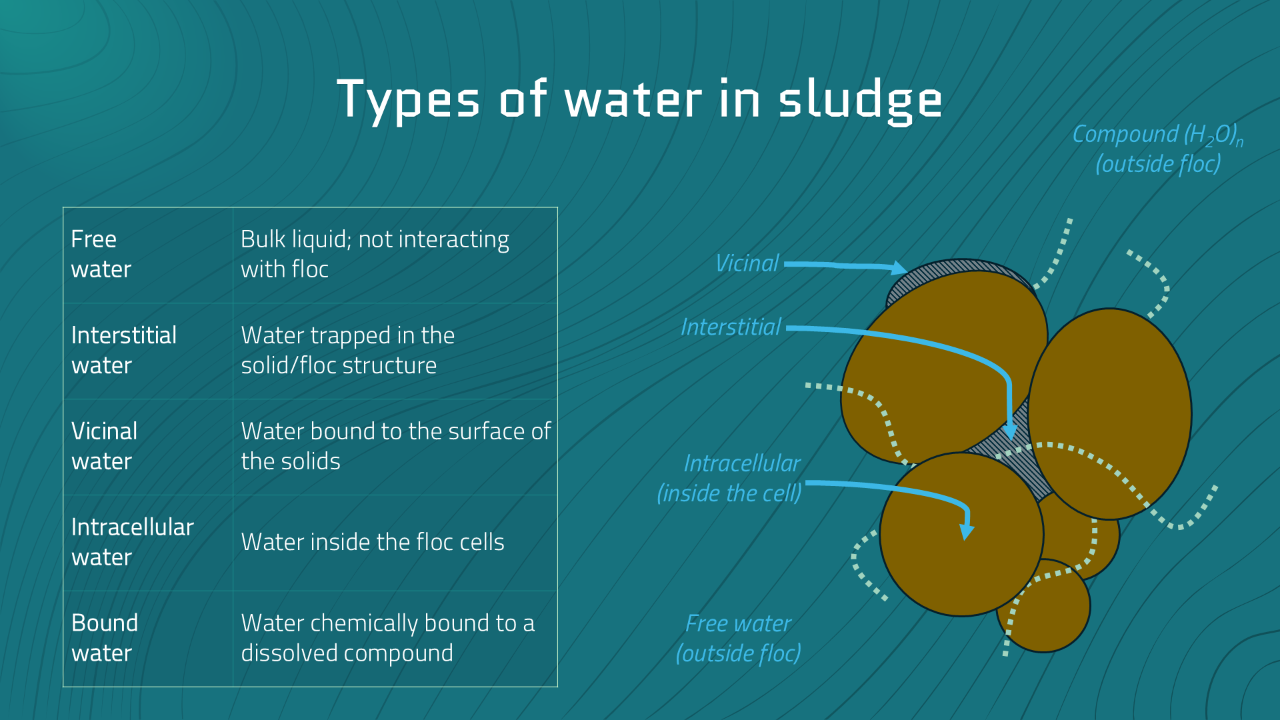

- The type(s) of water found in the sludge. There are five types of water: Free water, interstitial water, Vicinal water, Intracellular water, and Bound water. Their ease of removal varies. In general, free water and portions of interstitial water can be removed by mechanical dewatering.

- Presence of EPS. Extracellular polymeric substances (EPS) produced by bacteria interfere with the chemicals we use. Sludges with less EPS (e.g. primary sludge) are easier to dewater.

- Cations. The mechanisms at play are not fully understood yet, but the type and quantity of cations (positively charged particles in the sludge) seem to impact dewaterability.

- Upstream processes. Enhanced Biological Phosphorus Removal (EBPR), thermal hydrolysis, digestion, nutrient recovery, etc all change the sludge quality and impact dewaterability.

Thickening/ dewatering practices and the resulting performance will be different for different sludge qualities (sludge types). For this reason, you can’t just mimic what the neighboring WWTP does and expect similar results….your situation is unique. Despite this, there’s usually a ton of opportunity to improve practices, especially polymer use. While industry knowledge and best practices are well defined this info is often hard for staff to access and apply. That’s why I’ve created a roadmap to help all WWTPs optimize polymer use and reduce the associated operating costs. It gathers all the industry knowledge and presents it in an easy-to-follow format. Download it for free here.