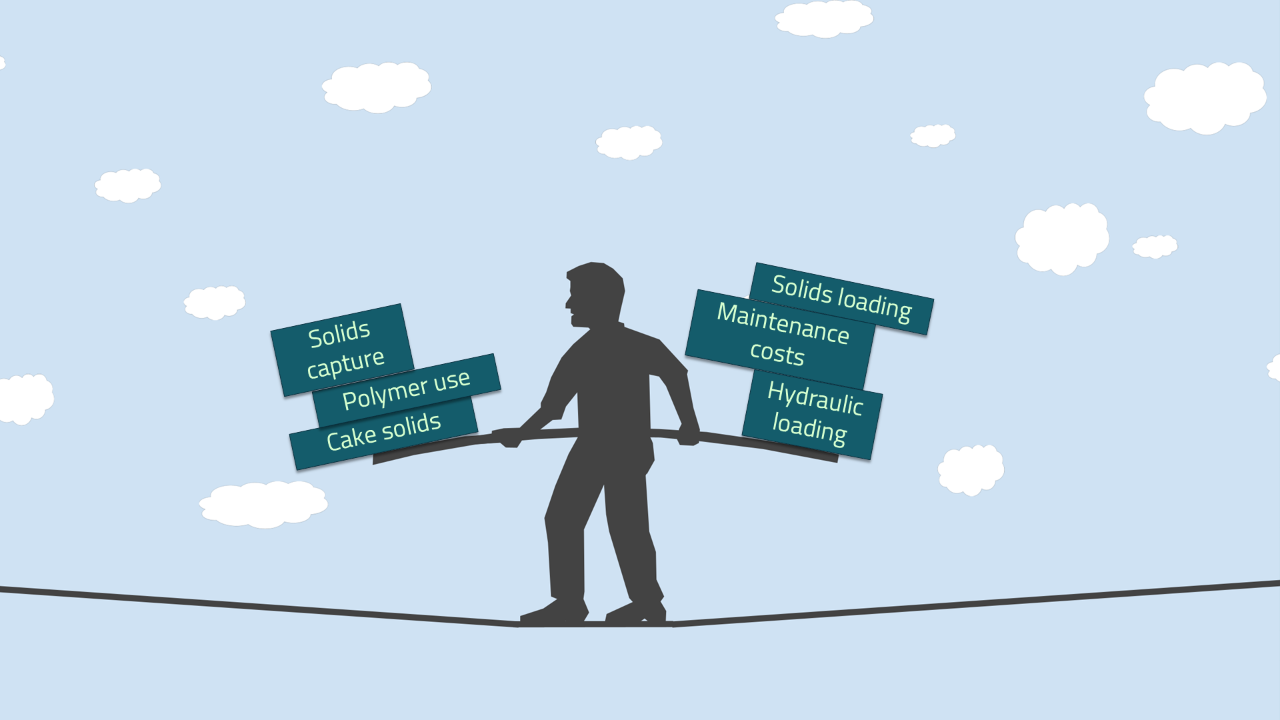

Walk the dewatering tightrope confidently: Using KPIs

Jan 21, 2026

Thickening and dewatering are bookends of your residuals handling process. Your operational knowledge/skill here has direct, whole-plant impacts including treatment performance, permit compliance, and operating costs. Effective thickening/dewatering operation is a balancing act. Establishing good monitoring practices is critical to consistent performance and maintaining the right balance. Key Performance Indicators (KPIs) help monitor the “big” picture, long-range performance of your thickening/ dewatering practice. They will be the same parameters regardless of what equipment you are using. They include:

- Solids loading – the amount of solids sent to the process; we measure this as pounds per day or hour (lbs/day; lbs/hr)

- Hydraulic loading – the amount of water sent to the process; we measure this as gallons per day, often per unit area such as square foot (gpd/sf)

- Solids capture – the percent of solids lost (to the drain); we measure this as Percent

- Cake solids – the solids concentration of end product; we measure this as Percent solids

- Polymer use - amount of chemical used; we measure this as active pounds polymer per dry ton solid (lbs/DT)

- Maintenance costs – equipment and manpower required for upkeep; we measure this as Dollars per dry ton processed ($/DT)

Once KPI’s are established you can use them to spot opportunities to improve and monitor progress. There’s usually a ton of opportunity to improve, especially in polymer use. While industry knowledge and best practices for polymer use are well defined this info is often hard for staff to access and apply. That’s why I’ve created a roadmap to help all WWTPs optimize polymer use and reduce the associated operating costs. It gathers all the industry knowledge and presents it in an easy-to-follow format. Download it for free here.